WHAT SETS

ANATOL AUTOS APART

NO AIR COMPRESSOR

MINIMAL AIR COMPONENTS

PROFITABILITY

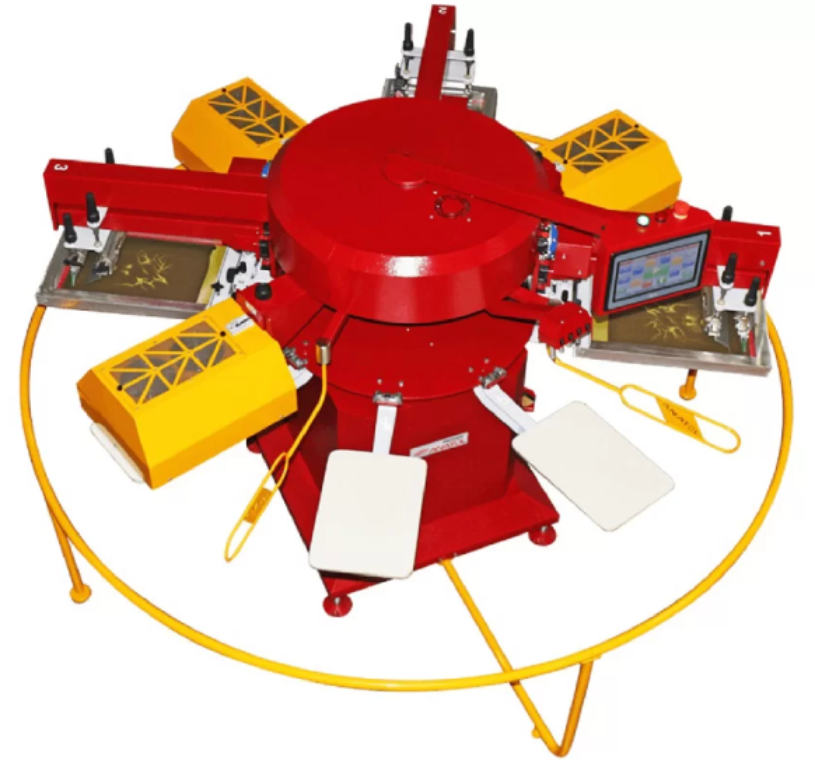

It’s not ideal. Compressed air is inherently inefficient (as much as 90% inefficient, according to the US Department of Energy), and requires a costly compressor and chiller setup with its own maintenance and reliability concerns. For a manufacturing application like t-shirt printing, a good compressed air setup may cost $5,000 - $10,000, or even more.

We do things differently

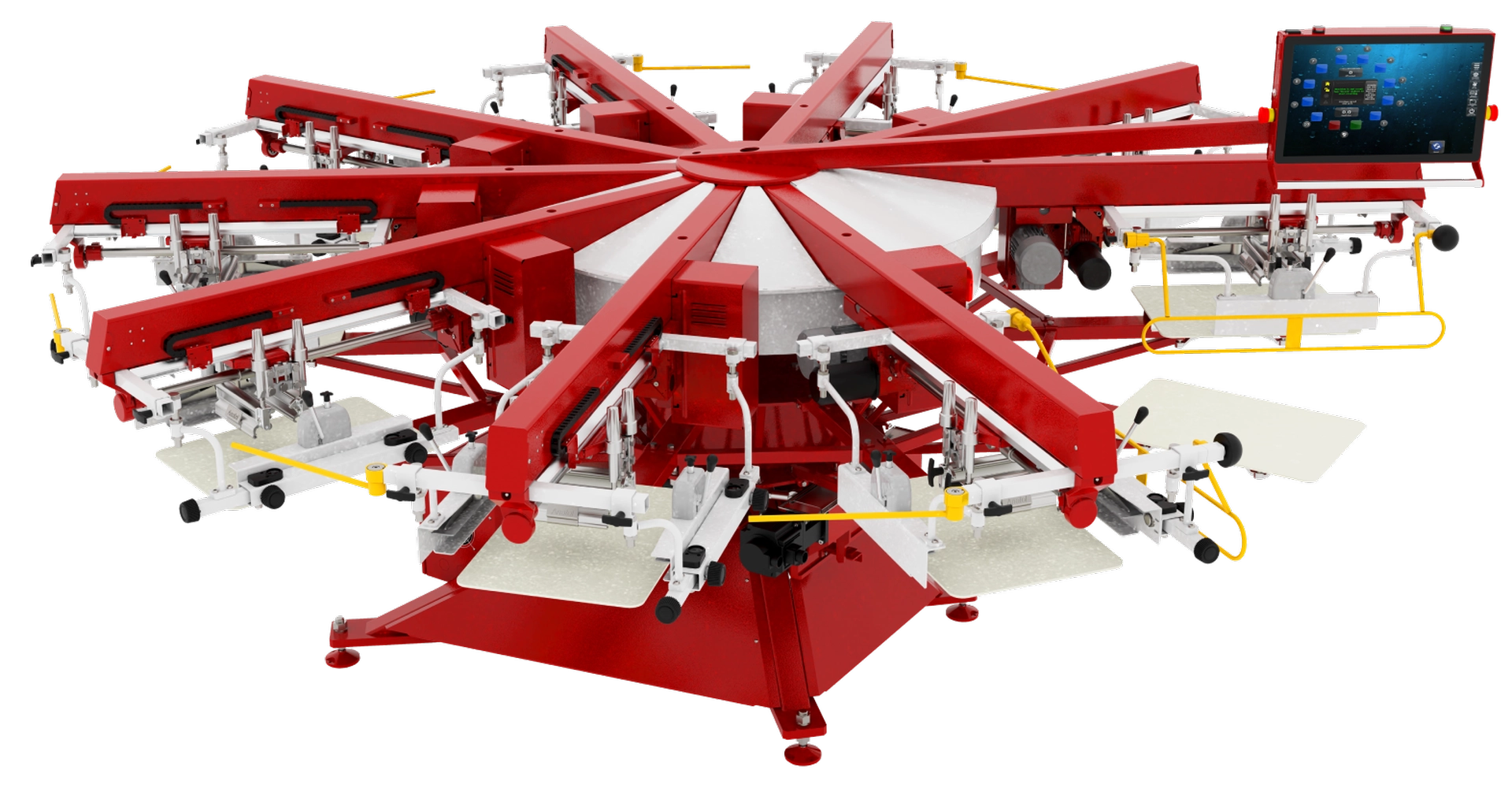

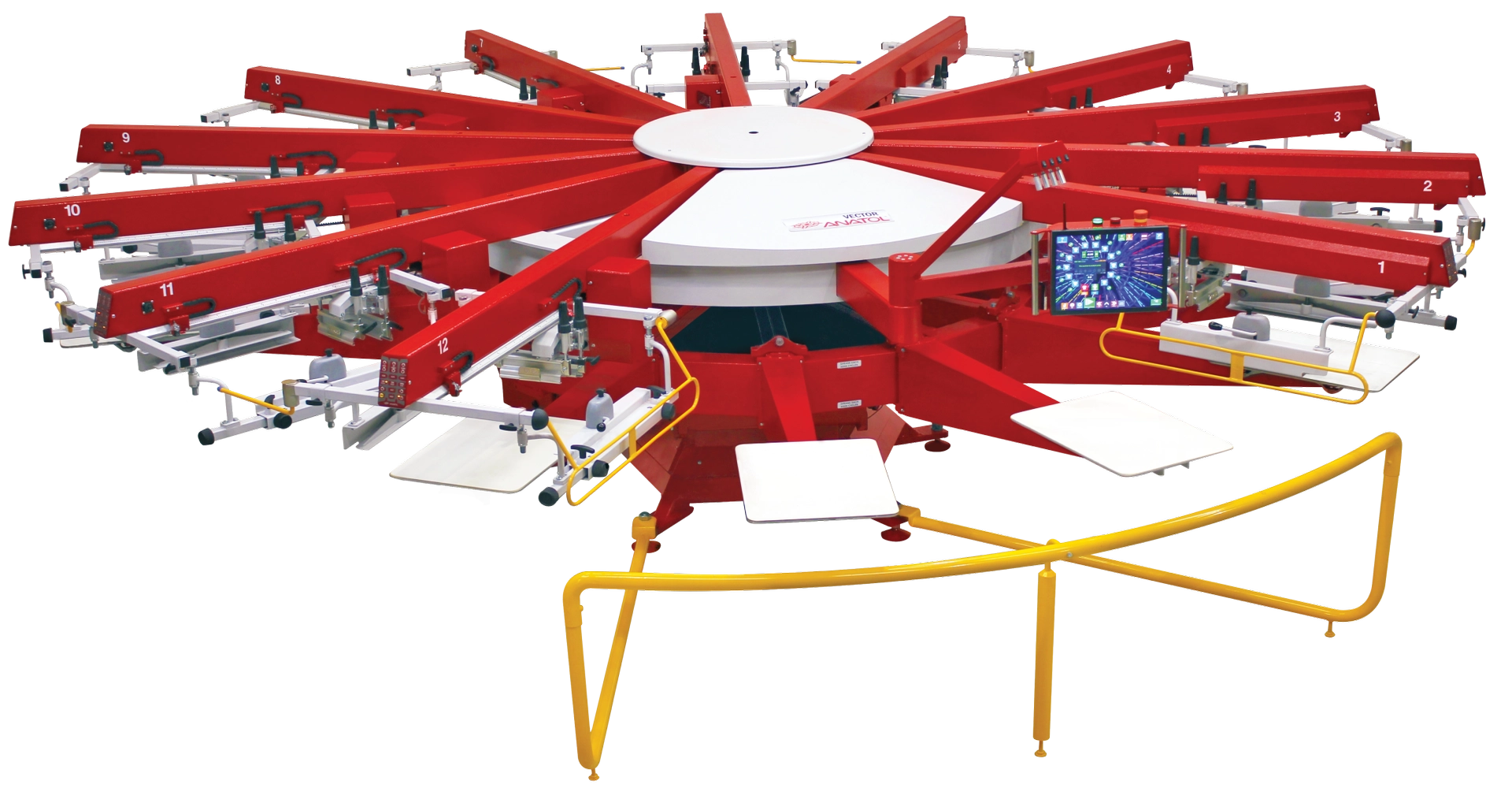

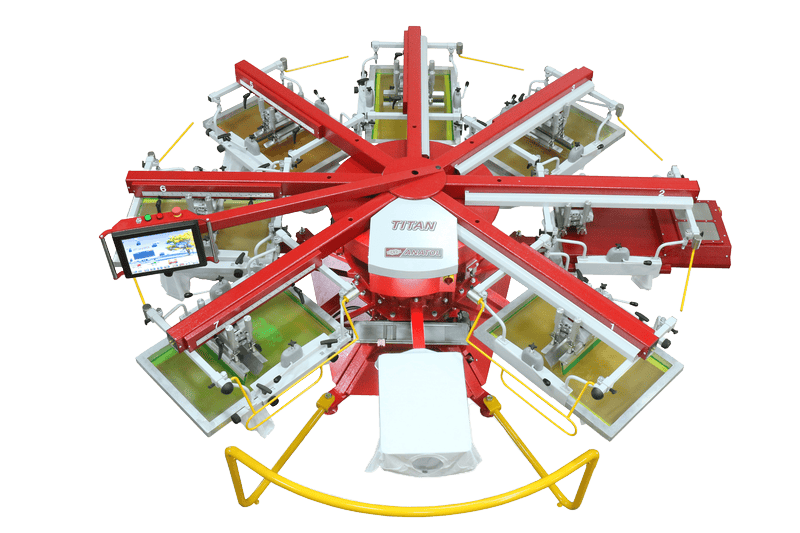

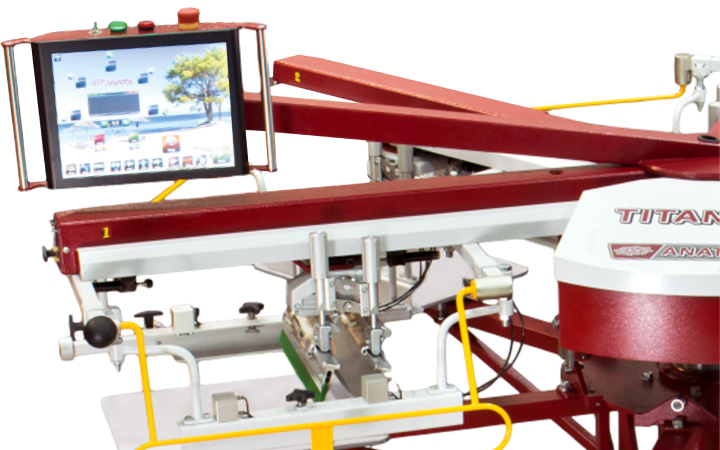

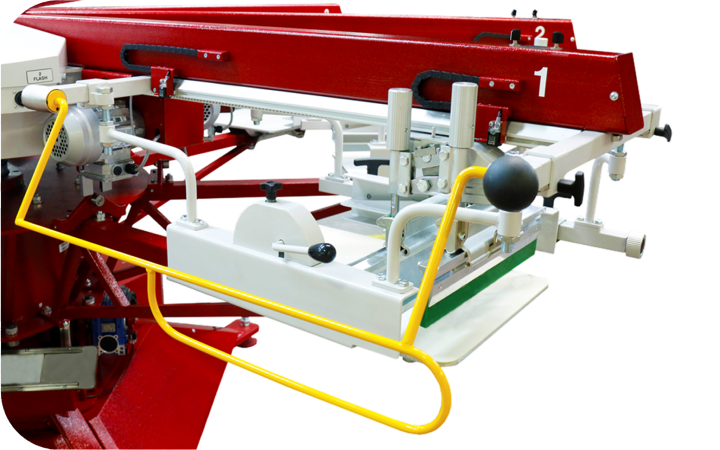

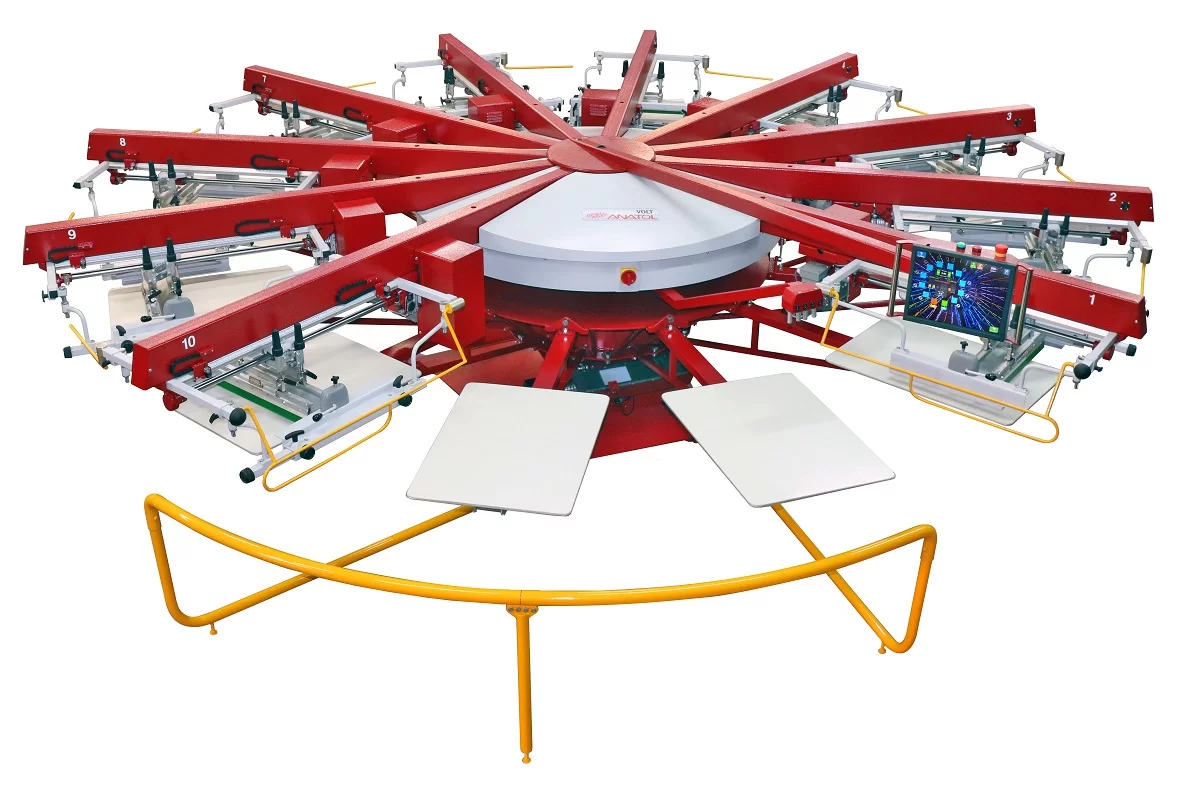

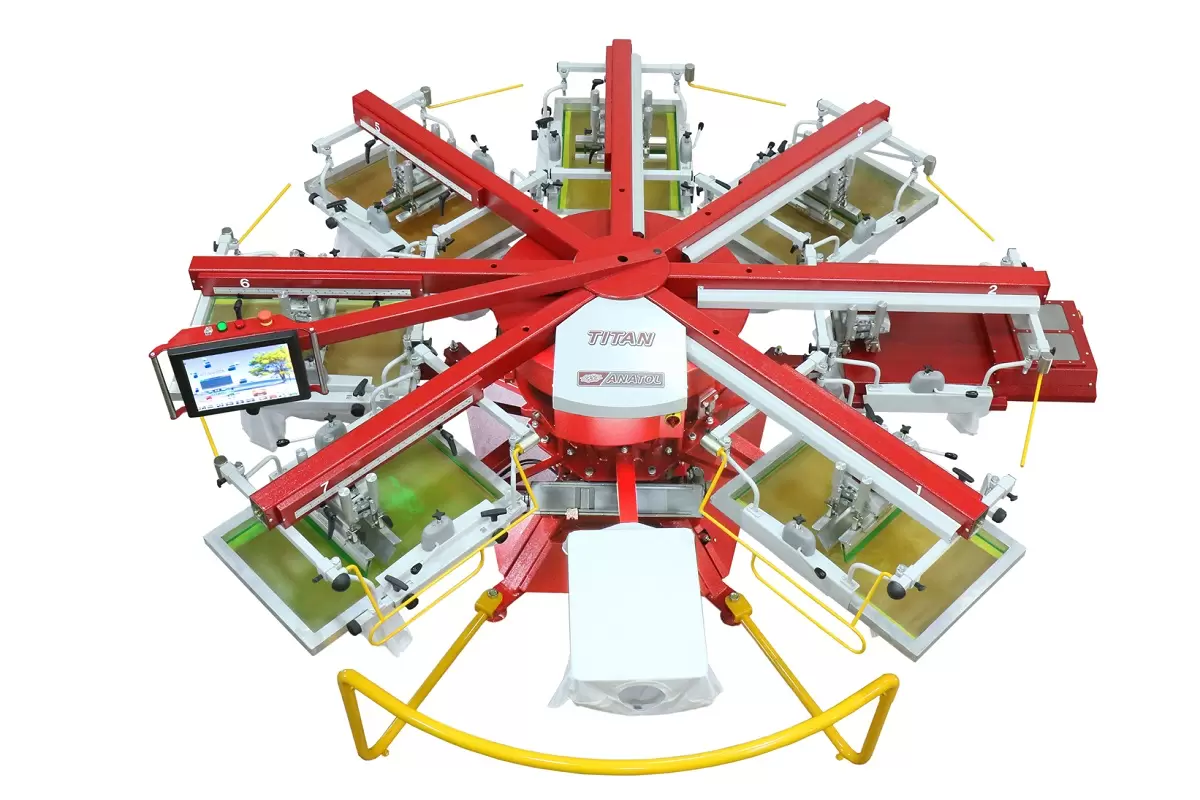

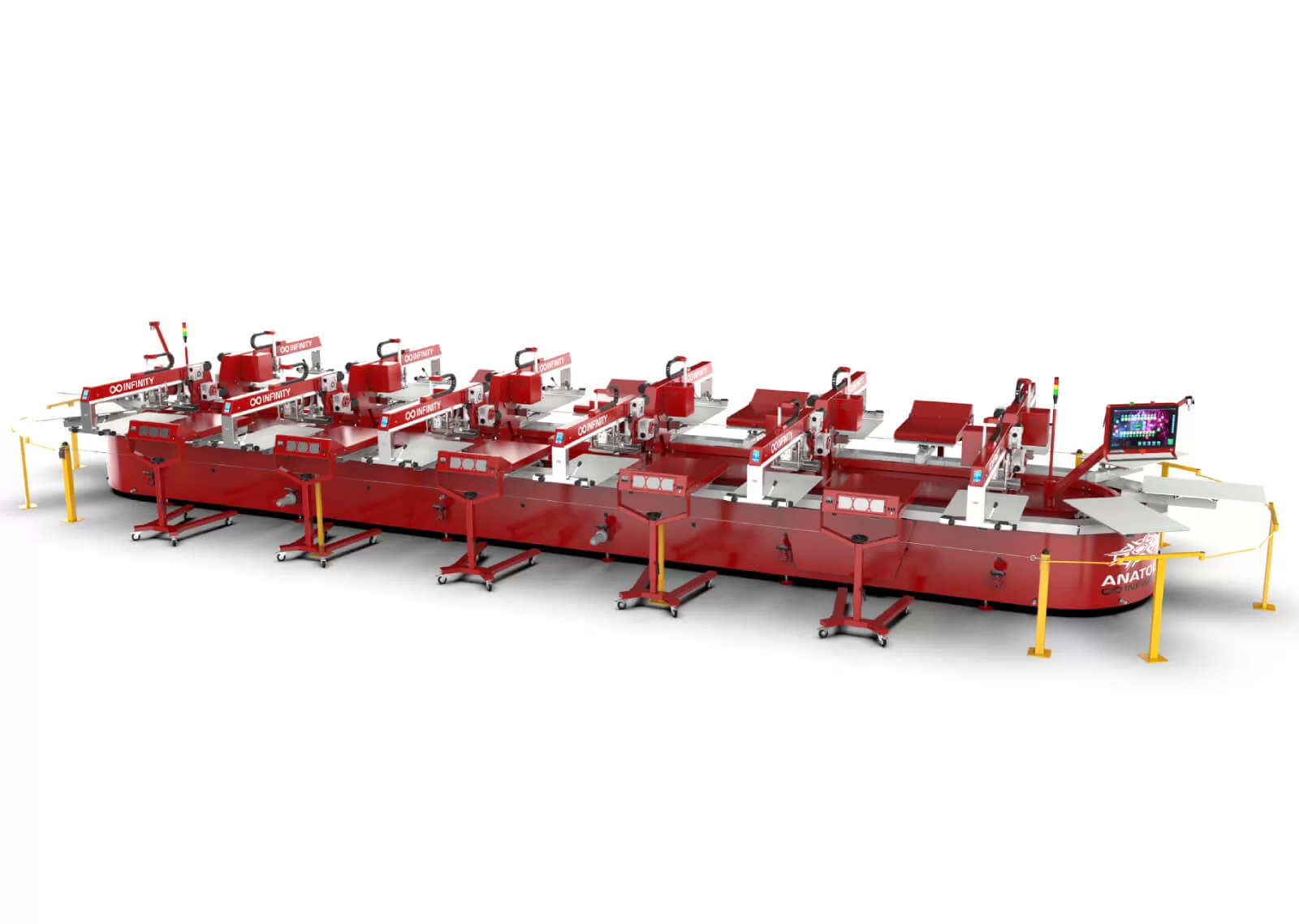

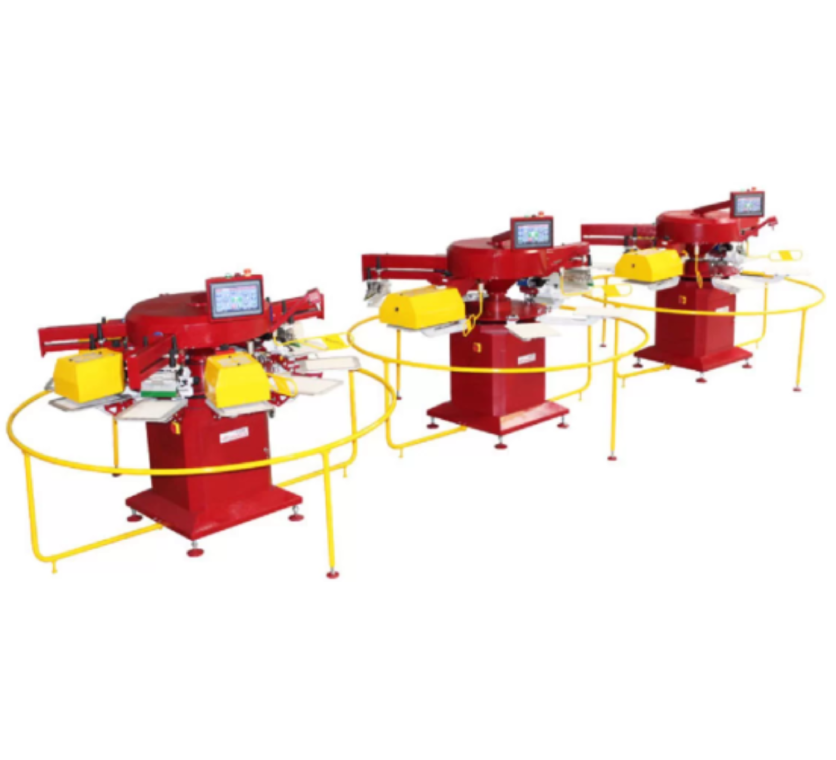

Our TITAN and VECTOR series of automatic screen printing presses greatly reduce air consumption, using only 1 or 2 air cylinders per print head (depending on configuration). Fewer pneumatic components means you spend more time printing and making money, and less time ordering and installing spare parts.

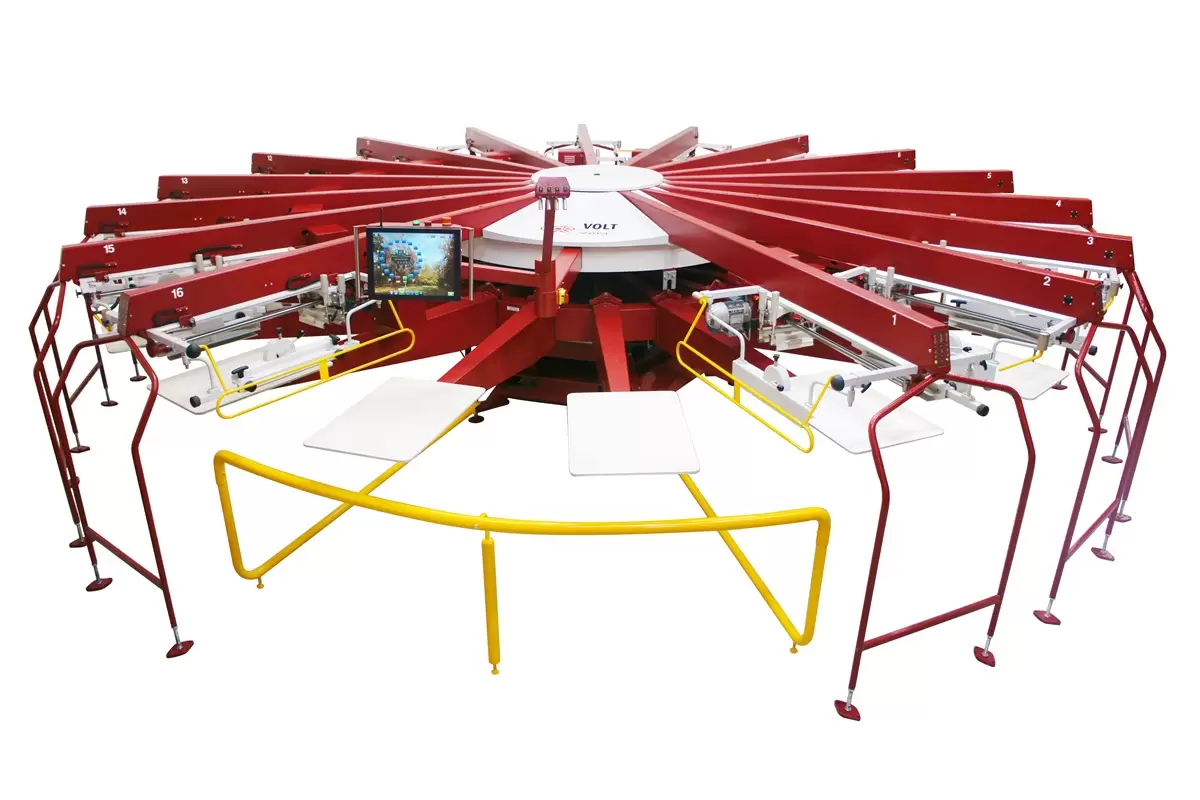

Our ALL-ELECTRIC VOLT automatic press goes one step further: it eliminates the need for compressed air completely. 100% electric operation means you get a smoother, quieter, more consistent and reliable press, driven by industrial-grade servo and AC-electric motors.The VOLT delivers these advantages while maintaining electrical consumption rates comparable to, and sometimes even lower than, competing pneumatic machines. That means you can ditch the air compressor and get a more capable machine, without worrying about increasing your power bill.

HEAR FROM OWNERS AND OPERATORS

WANT TO LEARN MORE?

Contact Us